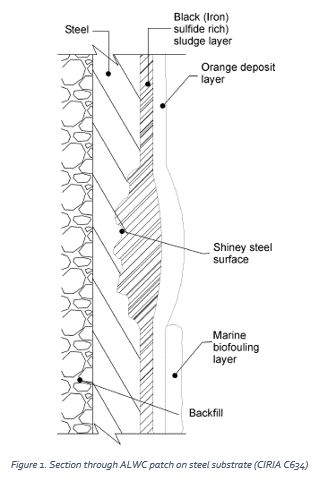

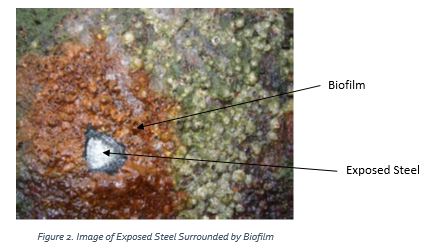

Accelerated Low Water Corrosion (ALWC) is a relatively new phenomenon, and an extreme form of aggressive corrosion, that majority of the time occurs slightly above Lowest Astronomical Tide (LAT) level, and is reported to have occurred along submerged sections. The occurrence is on unprotected steel in tidal areas. The cause of this is due to bacterial activity, and is therefore a microbial influenced corrosion (MIC). This occurs when sulphate resisting bacteria, an anaerobic bacteria, grow on steel forming a colony, if growth is sustained for long enough it forms a biofilm. This patch of bacteria does not directly consume the steel; however, it promotes and aggressively increases the rate of corrosion as it makes the ideal environment for it.

According to CIRIA C634 this process is random, and a successful method for predicting its occurrence has not been developed. Cases of ALWC have been reported from around the world in all tidal areas, and cause of its occurrence has not been truly understood. Its high variability is baffling as variation occurs in the local geography, where some piles are found with ALWC and some piles within the same vicinity are found to be free of it. The time scale is variable also as it is a multi-stage process and not linear like in table 2, which underestimates ALWC, as the rate of corrosion varies depending on the micro-environment. However, once the biofilm has formed rates of metal wastage is very high, making it possible to see patches within a couple of years. As a rule of thumb localised corrosion rates are 1.5 to 3 times more than the general uniform corrosion rates.

Currently the only reliable method of detecting ALWC is by visual inspection together with residual wall thickness measurements. ALWC occurs as localised patches of damage, identified by a characteristic, poorly-adherent orange corrosion product over a 'soupy' black underlayer associated with rapid metal thinning.

The strategy for management of ALWC will depend on whether the structure is new built or an existing structure. The corrosion protection measures that are currently applicable to ALWC are those based on conventional corrosion control methods such as cathodic protection (CP) and coatings of various types.